Manufacturing and industry have used 3D technology for product design. The prop design industry is more traditional than manual, using clay or oil soil development. However, the traditional doll design and development time is long, and the process of verification and modification is also full of variables. Nowadays, 3D technology is applied to props design, which changes the appearance of past props.

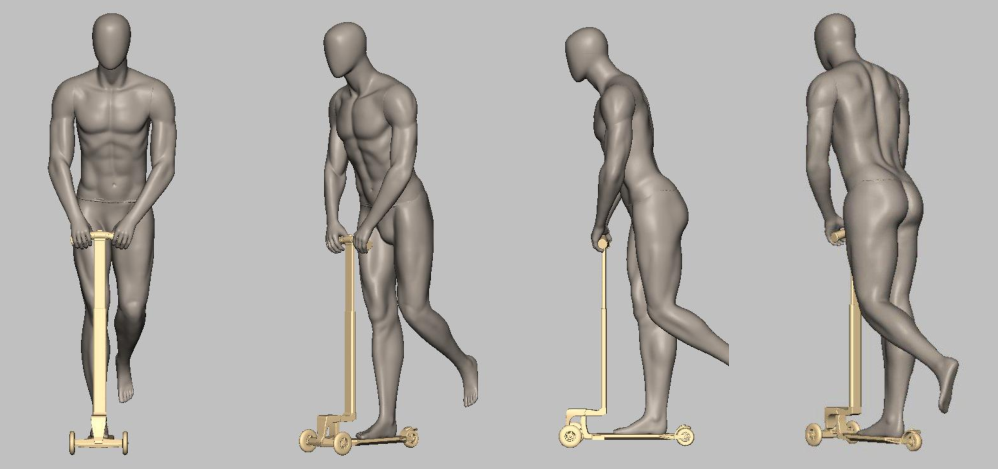

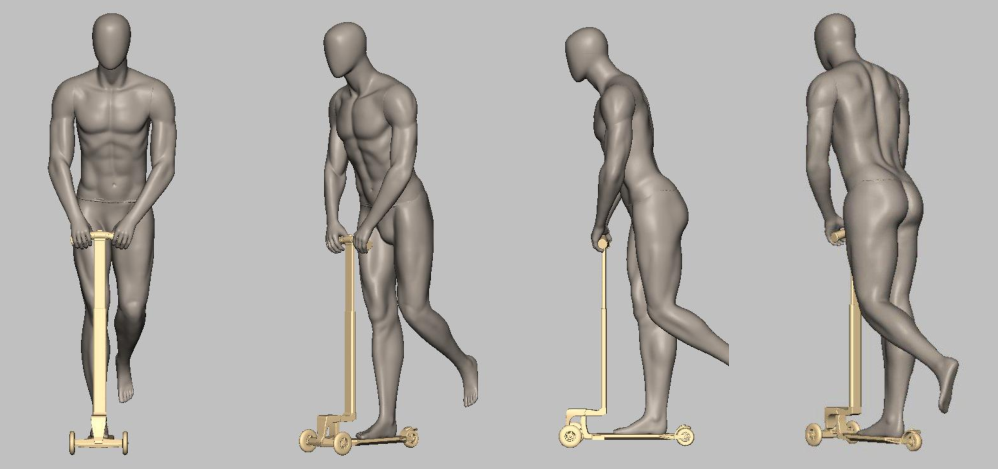

3D scanning: 3D scanning reverse engineering technology, which can scan according to the posture of people or other props, which greatly saves design time

3D design: The scanned 3D data is transmitted through the design software, and the digital engraving pen technology is used to modify the rough and detail.

3D printing: LEILEI3D printing center equipment, can provide monochrome or full color doll proofing service. 3D printed dolls are accurate in size and scale, presenting the perfect details, and decision makers can make the most accurate assessment based on the entity.

Mass production: We have our own factory. After the sample is confirmed, we can also make molds such as resin or plastic according to the 3D model and enter into mass production, thus reducing costs and saving time.